Technical Analysis:

The broad purpose of technical analysis is:

- To ensure that the project is technically feasible in the sense that all the inputs required to set up the project are

available - To facilitate the most optimal formulation of the project in terms of technology, size, location and so on.

Technical analysis is essential to ensure that necessary physical facilities required for production will be available and the best possible alternatives is selected to procure them. These are to be assessed by common sense, experience and discussions with the promoters

- Manufacturing Process / Technology

- Technical arrangement

- Size of the plant

- Product Mix

- Selection of Plant and Machinery

- Procurement of Plant and Machinery

- Plant lay out

- Location of the plant.

- Land

- Raw Material

- Market

- Labour

- Utilities such as water, Power, fuel etc.

- Effluent disposal

- Transportation

- Schedule of Project Implementation

- Manufacturing Process / Technology

- If a product can be manufactured by using alternative raw materials with alternative process routes, a comparative study should be done to choose the most suitable process depending upon the quality of product required, its end use.

- If a product is to be manufactured by a particular process for the first time in the country, necessary study should be done about the success of the process in other countries.’

Appropriateness of Technology

It refers to those methods of production which are suitable to local economic, social and cultural conditions

Technology should be evaluated in terms of:

Whether the technology utilizes local raw materials?

Whether the technology utilizes local man power?

Whether the goods and services produced cater to the basic needs?

Whether the technology protects ecological balance?

Whether the technology is harmonious with social and cultural conditions?

- Technical arrangement

- Technical arrangement made to obtain technical know how required for the proposed project.

- Support to be provided by technical collaborators in planning and designing of the project

- Selection and procurement of equipment, installation and operation of the plant, training etc.

- Collaborator has agreed to provide the benefits of research and development.

- Any restriction imposed by collaborator (Exports etc.)

- Size of the plant

Size of the plant depends on the manufacturing process, availability of raw material, capital investment, size of the market.

Size of the plant or capacity can be expressed in one of the following terms:

| 1 | With Respect to the output

( quantity of finished product) |

Pulp and paper, Cement, Steel, etc. |

| 2 | With Respect to input

( quantity of main raw material used) |

Sugar Mill, Cottonseed expeller unit, Solvent extraction plant.etc. |

| 3 | With respect to number or machines | Power looms, Spinning Mills, Textile Mills etc. |

The concept of economic size of the plant changes with the changes in technology, price structure, availability of raw material, demand of the product and other circumstances.

- Product Mix

Product mix or product range depends upon market requirement of certain items may have to be done in different sizes and quality to suit different consumers.

If plant may have flexibility to change product mix according to changes in the market conditions, such flexibility may need additional investment, its impact on the viability of the project be analysed.

- Selection of Plant and Machinery

- Selection of plant and machinery should be done according to manufacturing process and size of the unit. Different stages of manufacturing process should have proper balance of capacity.

- A product has to pass through 4 stages and the capacity of proposed machinery for each stage is as under

| Production Cycle | ||||||

| Raw Material |

Stages |

I | II | III | IV | Finished Goods |

| Capacity | 90 | 80 | 60 | 80 | ||

The total capacity of the plant in above case will be considered as 60 units because the capacity in the third stage of process is only 60 units.

- Equipments for utilities (Power, water, fuel etc) should also have sufficient capacity to meet the requirements of main plant and machinery.

- Adequate provisions should also be made for tools and spares.

- Procurement of Plant and Machinery

- The machinery suppliers should be decided keeping in view the quality of the machine, the reputation of the suppliers, delivery schedule, payment terms , performance guarantee and other relevant matters.

- It is not always necessary to procure machinery from suppliers whose quotations are the lowest.

- If the project is being implemented on turnkey basis , the reputation of EPC contractor, main terms and conditions of contract to be analyzed.

- If promoters proposes to import second hand machinery a certificate from chartered Engineer giving details of its history, present performance, valuation, economic life and suitability of second hand machinery should be obtained.

- In order to have uninterrupted production, it should be ensured that satisfactory arrangements for repair have been made and necessary spare parts will be available in time.

- Plant layout

- Proper plant lay out can reduce manufacturing cost by savings time and money .

- Plant lay out be done in such a way that minimum time is taken in handling equipment , raw material, consumables, goods –in –process and finished goods.

- Location of the plant.

- Land

- Land should be sufficient for the proposed project and the future expansion plans.

- Load bearing capacity of the land should be ascertained.

- Proposed land should be non agriculture and approved for Industrial use.

- Raw Material

- The requirement of raw material at full capacity should be ascertained and it should be ensured that necessary raw material will be available at reasonable price.

- If raw material is bulky and difficult to transport, it is better to locate the plant near the source of raw material.

- Regular supply of raw material is very necessary for the successful operation of the plant.

- Market

- While deciding location of the project, a comparative study regarding transportation of raw material and finished products should also be done.

- If transportation of finished products is more difficult than its raw material, it may be better to set up project near to the market.

- Labour

- Sometimes skilled labour is not available at a particular place. If labour has to be obtained from outside ,arrangements to provide housing facilities analyzed.

- Utilities such as water , Power, fuel etc.

- Arrangement for utilities power, water, fuedl etc to be ensured. If there is shortage of power supply alternative arrangement be way of Gen Sets etc be ensured.

- Effluent disposal

- The problem of effluent differs from industry to industry depending on nature and quantity of effluent.

- It should be ensured that necessary treatment is provided the effluent unit.

- Transportation

- If the proposed site is not connected with main road, an approach road may have to be laid from the site to the main road.

- The quality of road may be decided keeping in view the quantum of goods to be transported.

- If the unit proposes to buy their own vehicles cost benefit analysis be made, by calculating deprecation, interest and other expenses of maintaining vehicle compared to vehicles engaged on hire basis.

Schedule of Project Implementation

- The Project Evaluation and Review Technique ( PERT) or Critical Path Method (CPM) helps in proper planning , scheduling and controlling various activities essential for the execution of the project.

- All possible activities from project identification to commencement of production should be listed.

- It should be ensued that all the activities have been included and the time schedule given by the promoter is reasonable.

- Arrangement should be made to procure necessary raw material inputs like raw material, power, labour etc appropriate time so that plant does not remain idle and the implementation may commence soon as the installation of the plant is completed.

Technical Analysis Solutions in Software Development

Many a software project has failed due to an incomplete or inaccurate analysis process, especially technical analysis. Technical Analysis is a key step while developing a software application. It can be useful to-

- Confirm with the customer that we have gathered all business requirements accurately, and begin with designing and building the application after approval from the customer.

- It can be used by the Designers and Developers as a reference when building the application.

- It can be used by the client to verify that the final application actually matches what was initially agreed upon.

Components of Technical Analysis

There are two parts to Technical Analysis – drafting an Application Specification Document and generating Use Cases.

An Application Specification Document is usually derived from the Requirements Documentation from a Business Analyst. This document briefly specifies various features of the application, details parameters of how the application will be built, etc.

A sample structure of an Application Specification Document for a typical Web Development project would be as follows:

- Introduction

- Background

- Purpose

- Scope

- Definitions, Acronyms and Abbreviations

- References

- Overview

- Overall Description

- Use-Case Model Survey

- Assumptions and Dependencies

- Specific Requirements

- Non-functional Requirements

- Browser Compatibility

- Layout

- Graphics and Web Design

- Resolution

- Log History Analysis

- Cookies

- SMTP Server

- Secure Sockets Layer

- Accessibility

- Performance

- Payment Schedule

Depending on the project, you may need to elaborate or discard a few of these points but generally, this is how a Software Requirements Specification is laid out. It shows the intended behavior of the project and behavior can be expressed in the form of tasks, functions or services

technical-analysis-components-technical-arrangement-technical-analysis-components-technical-arrangement-solutions-use-cases-solutions-in-software-development technical-analysis-components-technical-arrangement-technical-analysis-components-technical-arrangement-solutions-use-cases-solutions-in-software-development

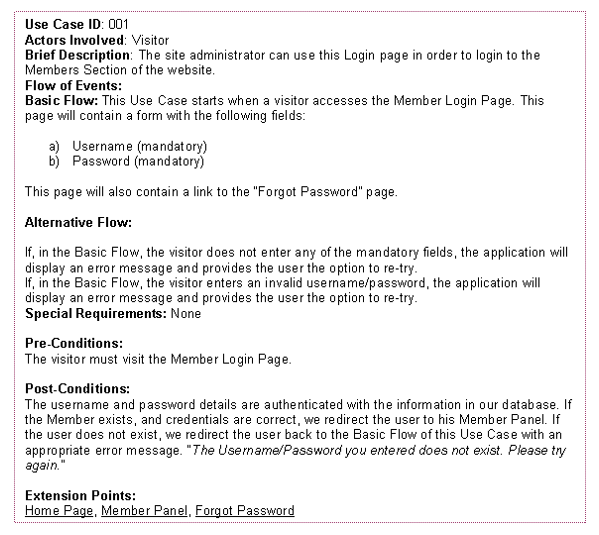

Use Cases

Use Cases are documents that help capture and detail requirements of the project. They are usually written in casual English for easy comprehension but when required, Flow Charts, Pseudo-Code, etc may be used to explain features in the Use Case. Use Cases are now a widespread practice that originally came from the Object-Oriented Programming Community.

Use Cases define goal-based relationships between actors and various functions in the application. An actor is a term that comes from UML. They are the external entities who use the application – visitors, administrators, staff, an external interacting application, etc. There are usually two types of actors – a Primary actor and a Secondary actor. A Primary Actor is one who requires assistance of the system for their goal to be satisfied. A Secondary Actor is one who the system needs assistance from in order to help Primary Actors achieve their goal.

Every Use Case needs to describe in detail the necessary interaction required between various actors and the application in order to deliver a service that satisfies an actor’s goal. A Use Case also needs to detail any possible alternate flows that could help an actor satisfy his goal. Alternate flows also need to describe methods that could lead to a failure of the application due to errors, etc.

System Internals are not part of a Use Case. A Use Case merely describes the actor, an actor’s possible interaction with the application, optionally the goal that the actor may have set out to achieve and various ways of achieving it.

There are many formats for Use Cases. A sample Use Case for a login feature would be as follows: