FILTER VALIDATION

Do you know Pharmaceutical Filter validation importance? Pharmaceutical processes are validated processes to assure a reproducible product within set specifications. Equally important is the validation of the filters used within the process, especially the sterilizing grade filters, which, often enough, are used before filling or the final processing of the drug product. In its Guideline on General Principles of Process Validation, 1985, and Guideline on Sterile Drug Products Produced by Aseptic Processing, 1987, the FDA makes plain that the validation of sterile processes is required by the manufacturers of sterile products. Sterilizing grade filters are determined by the bacteria challenge test. This test is performed under strict parameters and a defined solution (ASTM F 838-83).

In any case, the FDA nowadays also requires evidence that the sterilizing grade filter will create a sterile filtration, no matter the process, fluid or bioburden, found. This means that bacteria challenge tests have to be performed with the actual drug product, bioburden, if different or known to be smaller than B. diminuta and the process parameters. The reason for the requirement of a product bacteria challenge test is threefold. First, the influence of the product and process parameters to the microorganism has to be tested. There may be cases of either shrinkage of organisms due to a higher osmolarity of the product or prolonged processing times. Second, the filter’s compatibility with the product and the parameters has to be tested. The filter should not show any sign of degradation due to the product filtered. Additionally, rest assurance is required that the filter used will withstand the process parameters; e.g., pressure pulses, if happening, should not influence the filter’s performance.

Third, there are two separation mechanisms involved in liquid filtration: sieve retention and retention by adsorptive sequestration. In sieve retention, the smallest particle or organism size is retained by the biggest pore within the membrane structure. The contaminant will be retained, no matter the process parameters. This is the ideal. Retention

by adsorptive sequestration depends on the filtration conditions. Contaminants smaller than the actual pore size penetrate such and may be captured by adsorptive attachment to the pore wall. This effect is enhanced using highly adsorptive filter materials, for example,

Glassfibre as a prefilter or Polyamide as a membrane. Nevertheless, certain liquid properties can minimize the adsorptive effect, which could mean penetration of organisms. Whether the fluid has such properties and will lower the effect of adsorptive sequestration and may eventually cause penetration has to be evaluated in specific product bacteria challenge tests.

Before performing a product bacteria challenge test, it has to be assured that the liquid product does not have any detrimental, bactericidal or bacteriostatic, effects on the challenge organisms. This is done utilizing viability tests. The organism is inoculated into the product

to be filtered at a certain bioburden level. At specified times, the log value of this bioburden is tested. If the bioburden is reduced due to the fluid properties, a different bacteria challenge test mode becomes applicable. If the reduction is a slow process, the challenge test will

be performed with a higher bioburden, bearing in mind that the challenge level has to reach 107 per square centimeter at the end of the processing time. If the mortality rate is too high, the toxic substance is either removed or product properties are changed. This challenge fluid is called a placebo. Another methodology would circulate the fluid product through the filter at the specific process parameters as long as the actual processing time would be. Afterwards, the filter is flushed extensively with water and the challenge test, as described in ASTM F838-38, performed. Nevertheless, such a challenge test procedure would be more or less a filter compatibility test.

Besides the product bacteria challenge test, tests of extractable substances or articulate releases have to be performed. Extractable measurements and the resulting data are available from filter manufacturers for the individual filters. Nevertheless, depending

on the process conditions and the solvents used, explicit extractable tests have to be performed. These tests are commonly done only with the solvent used with the drug product but not with the drug ingredients themselves, because the drug product usually

covers any extractables during measurement. Such tests are conducted by the validation services of the filter manufacturers using sophisticated separation and detection methodologies, as GC-MS, FTIR, and RP-HPLC. These methodologies are required, due to the fact that the individual components possibly released from the filter have to be identified and quantified. Elaborate studies, performed by filter manufacturers, showed that there is neither a release of high quantities of extractables (the range is ppb to max ppm per 10-inch element) nor have toxic substances been found. Particulates are critical in sterile filtration, specifically of injectables. The USP 24 (United States Pharmacopoeia) and BP (British Pharmacopoeia) quote specific limits of particulate level contaminations for defined particle sizes. These limits have to be kept and, therefore, the particulate release of sterilizing

grade filters has to meet these requirements. Filters are routinely tested by evaluating the filtrate with laser particle counters. Such tests are also performed with the actual product under process conditions to prove that the product, but especially process conditions, do

not result in an increased level of particulates within the filtrate.

Additionally, with certain products, loss of yield or product ingredients due to adsorption shall be determined. For example, preservatives, like benzalkoniumchloride or chlorhexadine, can be adsorbed by specific filter membranes. Such membranes need to be saturated by the preservative to avoid preservative loss within the actual product. This preservative loss e.g., in contact lens solutions, can be detrimental, due

to long-term use of such solutions. Similarly, problematic would be the adsorption of required proteins within a biological solution. To optimize the yield of such proteins within an application, adsorption trials have to be performed to find the optimal membrane

material and filter construction.

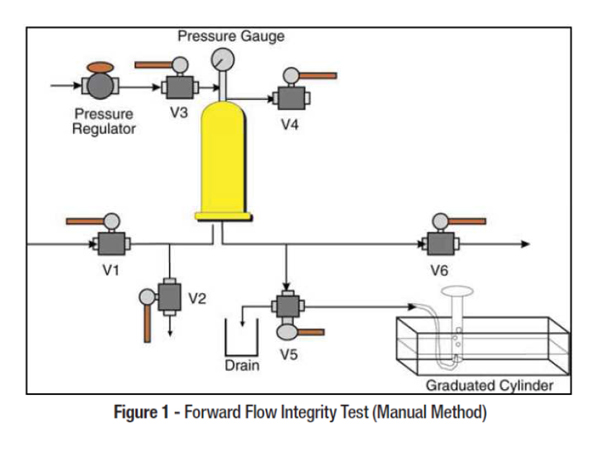

Cases that use the actual product as a wetting agent to perform integrity tests require the evaluation of product integrity test limits. The product can have an influence on the measured integrity test values due to surface tension, or solubility. A lower surface tension,

for example, would shift the bubble point value to a lower pressure and could result in a false negative test. The solubility of gas into the product could be reduced, which could result in false positive diffusive flow tests. Therefore, a correlation of the product as a wetting agent to the, water wet values has to be done, according to standards set by the manufacturer of the filter. This correlation is carried out by using a minimum of three filters of three filter lots. Depending on the product and its variability, one or three product lots are used to perform the correlation. The accuracy of such a correlation is enhanced by automatic integrity test

machines. These test machines measure with highest accuracy and sensitivity and do not rely on human judgement, as with a manual test. Multipoint diffusion testing offers the ability to test the filter’s performance and, especially, to plot the entire diffusive flow graph through the bubble point. The individual graphs for a water-wet integrity test can now be compared to the product wet test and a possible shift evaluated. Furthermore, the multipoint diffusion test enables the establishment of an improved statistical base to determine the product wet versus water-wet limits.

Look out here Pharmaceutical FILTER INTEGRITY TESTING – FDA Guideline on Sterile Drug Products

Pharmaceutical Filter Validation References:

- Cooper and Gunn’s. Tutorial Pharmacy by S.J.Carter.

- Pharmaceutical engineering; K. Sambamurthy

- Pharmaceutical engineering; principles and practices, C.V.S. Subrahmanyam

- Encyclopedia of pharmaceutical technology, vol 3, edited by James Swarbrick.

- Pikal, M.J.; Lukes, A.L.; Lang, J.E. Thermal decomposition of amorphous beta-lactam antibacterials. J. Pharm. Sci. 1977, 66, 1312–1316.

- Pikal, M.J.; Lukes, A.L.; Lang, J.E.; Gaines, K. Quantitative crystallinity determinations of beta-lactam antibiotics by solution calorimetry: correlations with stability. J. Pharm. Sci. 1978, 67, 767–773.

- Pikal, M.J.; Dellerman, K.M. Stability testing of pharmaceuticals by high-sensitivity isothermal calorimetry at 25_C: cephalosporins in the solid and aqueous solution states. Int. J. Pharm. 1989, 50, 233–252.

- Incoming searches:

- filter validation ppt,

filter validation pdf,

brevundimonas diminuta filter validation,

filter validation millipore,

filter validation fda,

sterile filtration validation protocol,

bacterial retention testing of sterilizing-grade filters,

sterile filtration definition,