Fermentation Systems: Powering Bioprocessing and Biopharmaceutical Production

Fermentation systems are a crucial category of bioprocessing equipment that plays a fundamental role in the production of various biopharmaceuticals, enzymes, biofuels, and other bioproducts. These systems provide a controlled environment for the cultivation and growth of microorganisms, such as bacteria, yeast, or fungi, which are used to produce valuable products through fermentation processes. In this comprehensive guide, we will explore fermentation systems in detail, covering their types, components, working principles, applications, and the critical role they play in advancing bioprocessing and biopharmaceutical production.

Table of Contents

Introduction to Fermentation Systems

Understanding Fermentation

The Importance of Fermentation Systems

Role of Fermentation in Bioprocessing

Types of Fermentation Systems

Batch Fermentation

Continuous Fermentation

Fed-Batch Fermentation

Components of Fermentation Systems

Fermenters and Bioreactors

Sensors and Controls

Agitation and Aeration Systems

Sterilization and CIP Systems

Working Principles of Fermentation Systems

Microbial Growth and Metabolism

Oxygen Transfer and Mixing

Temperature Control

pH and Nutrient Regulation

Applications of Fermentation Systems

Pharmaceutical and Biopharmaceutical Production

Enzyme and Biochemical Manufacturing

Biofuel Production

Food and Beverage Industry

Challenges and Advances in Fermentation Systems

Scaling Up and Down

Contamination Control

Automation and Process Monitoring

Advances in Microbial Engineering

Future Trends in Fermentation Systems

Synthetic Biology and Strain Optimization

Sustainability and Bioprocess Intensification

Integration with Industry 4.0 Technologies

Personalized Medicine and Precision Fermentation

Conclusion

1. Introduction to Fermentation Systems

Understanding Fermentation

Fermentation is a biological process wherein microorganisms, such as bacteria, yeast, or fungi, convert organic substances into valuable products by anaerobic or aerobic metabolism. This natural process has been harnessed by humans for centuries to produce a wide range of products, including alcoholic beverages, bread, and dairy products. In the context of bioprocessing and biopharmaceutical production, fermentation is a controlled and highly regulated process used to generate pharmaceuticals, enzymes, biofuels, and various biochemicals.

The Importance of Fermentation Systems

Fermentation systems, often referred to as fermenters or bioreactors, are designed to provide the optimal conditions required for the growth and metabolic activity of microorganisms. These systems are pivotal in ensuring the success of fermentation processes in a controlled and reproducible manner. The biopharmaceutical industry, in particular, heavily relies on fermentation systems for the production of biologics such as monoclonal antibodies, vaccines, and other therapeutic proteins.

Role of Fermentation in Bioprocessing

Fermentation serves as a critical step in bioprocessing, bridging the gap between laboratory-scale research and large-scale production. Fermentation systems enable the cultivation of microorganisms at various scales, from small laboratory fermenters to industrial-scale bioreactors. They offer precise control over environmental factors such as temperature, pH, dissolved oxygen levels, and nutrient supply, ensuring the optimal growth and productivity of microbial cultures.

2. Types of Fermentation Systems

Fermentation systems can be categorized into different types based on their operational mode:

Batch Fermentation

Operation: In batch fermentation, microorganisms are cultivated in a closed system with a fixed volume of nutrient medium. The entire process, from inoculation to product harvesting, occurs in a single batch.

Applications: Batch fermentation is commonly used in research and development, small-scale production, and when product variability is not a concern.

Continuous Fermentation

Operation: In continuous fermentation, fresh nutrient medium is continuously added to the system, while an equal volume of spent medium is removed at the same rate. This allows for a continuous flow of microorganisms and nutrients.

Applications: Continuous fermentation is suitable for large-scale production of consistent products, such as biofuels and certain chemicals.

Fed-Batch Fermentation

Operation: Fed-batch fermentation combines aspects of both batch and continuous processes. Nutrients are intermittently added to the system to maintain favorable growth conditions without diluting the culture.

Applications: Fed-batch fermentation is widely used in biopharmaceutical production to maximize product yield and control the growth rate of microorganisms.

The choice of fermentation type depends on factors such as the product being manufactured, scale of production, and process economics.

3. Components of Fermentation Systems

Fermentation systems are composed of several critical components that work in concert to facilitate microbial growth and product formation:

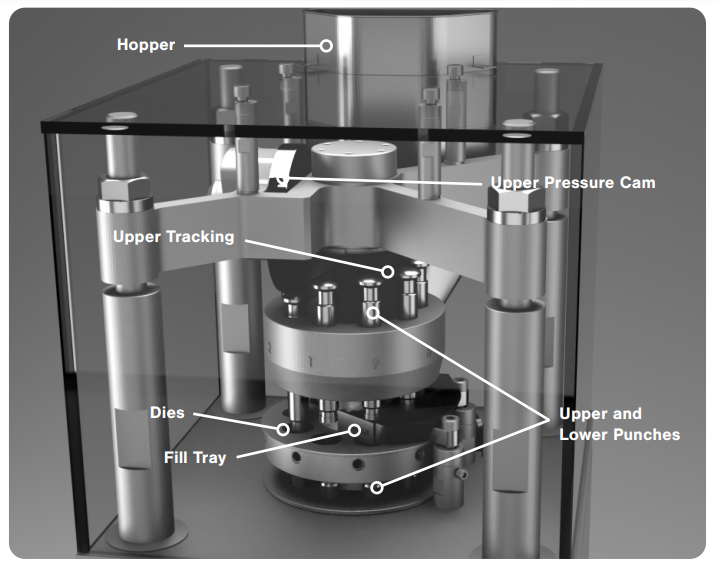

Fermenters and Bioreactors

Description: Fermenters and bioreactors are vessels designed to house microbial cultures. They come in various sizes and configurations, including benchtop fermenters for research and industrial-scale bioreactors for large-scale production.

Function: These vessels provide a controlled environment where temperature, pH, agitation, and aeration are regulated to support optimal microbial growth and product formation.

Sensors and Controls

Description: Sensors, such as pH probes, dissolved oxygen sensors, and temperature probes, monitor key process parameters in real time. Control systems adjust conditions based on sensor feedback.

Function: Sensors and controls maintain precise environmental conditions, ensuring that the microorganisms thrive and produce the desired product consistently.

Agitation and Aeration Systems

Description: Agitation systems, which typically include impellers or stirrers, ensure the even distribution of nutrients and oxygen throughout the culture. Aeration systems supply oxygen to support aerobic metabolism.

Function: Effective mixing and aeration promote microbial growth and prevent the formation of oxygen-deprived zones within the culture.

Sterilization and CIP Systems

Description: Sterilization systems, such as autoclaves, ensure that all components of the fermentation system are free from contaminants before the start of a new batch. Clean-in-place (CIP) systems clean and sanitize the equipment between batches.

Function: Sterilization and CIP systems are essential for preventing contamination and maintaining product purity.

4. Working Principles of Fermentation Systems

The operation of fermentation systems relies on several fundamental principles:

Microbial Growth and Metabolism

Description: Microorganisms, such as bacteria or yeast, require a nutrient-rich medium that provides essential nutrients like carbon, nitrogen, and minerals. The microorganisms metabolize these nutrients to generate energy and produce the desired product.

Function: Fermentation systems create an environment where microbial growth and metabolism can occur optimally.

Oxygen Transfer and Mixing

Description: Adequate oxygen supply is critical for aerobic fermentation, as it supports the production of energy and certain products. Mixing systems ensure that oxygen is distributed evenly throughout the culture.

Function: Oxygen transfer and mixing systems maintain the appropriate oxygen levels for microbial growth.

Temperature Control

Description: Temperature control is vital because microorganisms have specific temperature requirements for growth. Fermentation systems use heating and cooling mechanisms to maintain the desired temperature.

Function: Temperature control ensures that the culture remains within the optimal temperature range for microbial activity.

pH and Nutrient Regulation

Description: pH levels and nutrient concentrations must be carefully regulated to create a favorable environment for microbial growth. pH can impact enzyme activity, and nutrient levels affect growth rates.

Function: pH and nutrient regulation systems maintain the conditions necessary for microbial growth and product formation.

5. Applications of Fermentation Systems

Fermentation systems find diverse applications across various industries, including:

Pharmaceutical and Biopharmaceutical Production

Description: Fermentation systems are extensively used in the production of biopharmaceuticals such as monoclonal antibodies, therapeutic proteins, and vaccines.

Function: They provide a controlled environment for the cultivation of mammalian cells or microorganisms that produce biologics.

Enzyme and Biochemical Manufacturing

Description: Fermentation is employed to produce enzymes and biochemicals used in various applications, including food processing, detergents, and biofuels.

Function: These systems enable the efficient and cost-effective production of enzymes and biochemical products.

Biofuel Production

Description: Fermentation systems are utilized to convert biomass into biofuels such as ethanol, biodiesel, and biogas.

Function: They support the fermentation of sugars and organic materials to produce biofuels with potential environmental benefits.

Food and Beverage Industry

Description: Fermentation is integral to the production of a wide range of food and beverage products, including yogurt, cheese, bread, and alcoholic beverages.

Function: Fermentation processes enhance flavor, texture, and preservation in these products.

6. Challenges and Advances in Fermentation Systems

Fermentation systems have evolved significantly over the years, addressing challenges and incorporating advances to improve their efficiency and productivity:

Scaling Up and Down

Challenge: Transitioning from laboratory-scale fermentation to large-scale production can be complex due to differences in equipment, process optimization, and scale-up challenges.

Advances: Improved scaling methodologies, as well as the development of standardized components and systems, have made scaling up and down more manageable.

Contamination Control

Challenge: Maintaining sterility and preventing contamination is critical in fermentation. Contamination can result in batch failure and product loss.

Advances: Advances in sterilization technology, stringent aseptic techniques, and the use of single-use bioreactors have enhanced contamination control.

Automation and Process Monitoring

Challenge: Maintaining consistent and precise control of fermentation parameters can be challenging, especially in large-scale bioreactors.

Advances: Automation systems equipped with sensors and control algorithms enable real-time monitoring and adjustment of critical parameters, improving process robustness and reproducibility.

Advances in Microbial Engineering

Challenge: Strain development and optimization are essential for increasing product yields and improving the efficiency of microbial fermentation.

Advances: Advances in synthetic biology, genetic engineering, and strain development techniques have led to the creation of high-performing microorganisms.

7. Future Trends in Fermentation Systems

The future of fermentation systems is marked by several promising trends and innovations:

Synthetic Biology and Strain Optimization

Trend: Continued advancements in synthetic biology will enable the engineering of microorganisms with enhanced capabilities for producing valuable products.

Sustainability and Bioprocess Intensification

Trend: Bioprocessing is increasingly focused on sustainability, with efforts to reduce resource consumption and waste generation. Process intensification aims to enhance product yield and reduce production costs.

Integration with Industry 4.0 Technologies

Trend: The integration of Industry 4.0 technologies, including IoT sensors, data analytics, and machine learning, will enable smarter and more efficient fermentation processes.

Personalized Medicine and Precision Fermentation

Trend: In the field of biopharmaceuticals, personalized medicine and precision fermentation are emerging trends, where therapies are tailored to individual patients using advanced fermentation techniques.

8. Conclusion

Fermentation systems are at the forefront of bioprocessing and biopharmaceutical production, enabling the efficient and controlled cultivation of microorganisms for various applications. Their versatility, scalability, and ability to provide precise control over critical parameters make them indispensable tools in industries ranging from pharmaceuticals to food production. As advances in biotechnology continue to shape the future, fermentation systems will remain pivotal in harnessing the power of microorganisms to produce valuable products, drive sustainability, and improve healthcare.