Effective process validation contributes significantly to assuring drug quality. The basic principle of quality assurance is that a drug should be produced that is fit for its intended use.

This principle incorporates the understanding that the following conditions exist:

• Quality, safety, and efficacy are designed or built into the product.

• Quality cannot be adequately assured merely by in-process and finished-product inspection or testing.

As we have discussed effective process validation contributes significantly to assuring drug quality. The basic principle of quality assurance is that a drug should be produced that is fit for its intended use. Pharmaceutical Process Validation Protocol & Report Format Example PPT PDF is given here for autoclave and sterilization. First let us know what is Pharmaceutical Process Validation. Validation refers to establishing documented evidence that a process or system, when operated within established parameters, can perform effectively and reproducibly to produce a medicinal product meeting its pre-determined specifications and quality attributes. It is mandatory to have a system stock list put in place, the appropriate SOPs in place, and additionally to check the critical techniques and their documentation. Having a powerful efficient Computer System Validation System put in place will help ensure the stability of the electronic documents, allocate resources better and subsequently can yield long run cost discounts to the company.

Approach to Process Validation:

For purposes of this guidance, process validation is defined as the collection and evaluation of data, from the process design stage through commercial production, which establishes scientific

evidence that a process is capable of consistently delivering quality product. Process validation involves a series of activities taking place over the lifecycle of the product and process. This

guidance describes process validation activities in three stages.

• Stage 1 – Process Design: The commercial manufacturing process is defined during this stage based on knowledge gained through development and scale-up activities.

• Stage 2 – Process Qualification: During this stage, the process design is evaluated to determine if the process is capable of reproducible commercial manufacturing.

• Stage 3 – Continued Process Verification: Ongoing assurance is gained during routine production that the process remains in a state of control.

Validation Protocol:

A written plan stating how validation will be conducted, including test parameters, product characteristics, production and packaging equipment, and decision points on what constitutes acceptable test results. This document should give details of critical steps of the manufacturing process that should be measured, the allowable range of variability and the manner in which the system will be tested.

The validation protocol provides a synopsis of what is hoped to be accomplished. The protocol should list the selected process and control parameters, state the number of batches to be included in the study, and specify how the data, once assembled, will be treated for relevance. The date of approval by the validation team should also be noted.

In the case where a protocol is altered or modified after its approval, appropriate reasoning for such a change must be documented.

The validation protocol should be numbered, signed and dated, and should contain as a minimum the following information:

1. Title

2. Objective & Scope

3. Responsibility

4. Protocol Approval

5. Validation Team

6. Product Composition

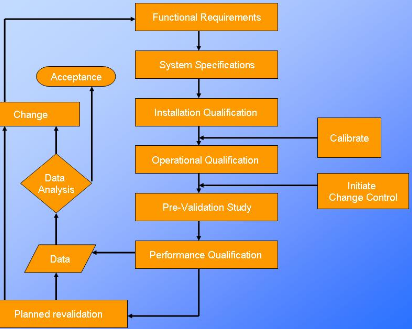

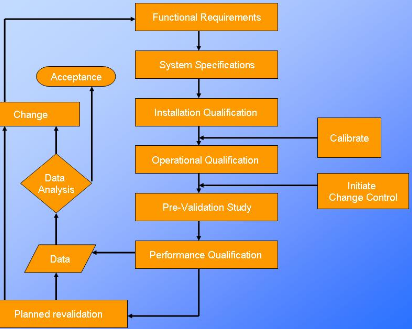

7. Process Flow Chart

8. Manufacturing Process

9. Review of Equipments / Utilities

10.Review of Raw Materials and Packing Materials

11. Review of Analytical and Batch Manufacturing Records

12. Review of Batch Quantities for Validation (Raw Materials)

13. Review of Batch Quantities for Validation (Packing Materials)

14. HSE Requirements

15. Review of Process Parameters

16. Validation Procedure

17. Sampling Location

18. Documentation

19. Acceptance Criteria

20. Summary

21. Conclusion

Process Validation Protocol – Pharmaceutical Template PDF PPT XLS

PROCESS VALIDATION PROTOCOL -Pharmaceutical (Autoclave)

1. PRE-EXECUTION APPROVAL

Successful completion of this protocol will provide documented evidence that all key aspects of the Autoclave used in LARGE VOLUME PARENTRALS SECTION adheres to appropriate application criteria, comply with standard operating procedures, and meet current Good Manufacturing Practices (cGMP) requirements.

1.1 SIGNATORY LIST

The signature below indicates approval of this protocol and its attachments for execution.

(Name & Designation, Signature, Date, Prepared By, Checked and Reviewed By, Approved By are the rows and columns you need to fill in the signatory list)

|

Name & Designation |

Signature |

Date |

|

|

|

|

| PreparedBy |

|

|

|

|

|

|

|

| Checkedand Reviewed By |

|

|

|

|

|

|

|

| ApprovedBy |

|

|

|

1.2 Validation Team

All individuals participating in the execution of this protocol must fill out a row in the table below. with all the details like Name & Designation, Responsibility, Signature & Initial along with the Date of the process.

Prepare the protocol and coordinate the validation study. Generate amendments to the protocol as required

Microbiological validation of the sterilization process. document the microbiological aspects of the study

Protocol training of operators and provide the resources for validation study

3.0 INSTRUCTIONS

3.1. General Instruction

All performers and reviewers must complete qualification forms using the following guidelines:

· Complete all items on a form in full, except the optional comment’s section.

· Document any deviation from defined protocols and expected results. Owner approval of protocol deviations must be documented before final approval signatures can be obtained.

· Write additional comments on an addendum sheet when there is not enough space on a form to accommodate all comments. Use these three steps when adding an addendum sheet.

1. Number the page alphanumerically.

2. Initial and date additions.

3. Insert the addendum sheet behind the original page.

· Make all entries in permanent black or blue ball pen.

3.2 Correcting Entries

If you need to make corrections on a form, use the procedures described below:

3.2.1 Correcting Short Entries

To correct a short entry [such as a single word or test result] on a form:

1. Draw a diagonal line, bottom left to upper right, through the miss entered or incorrect information.

2. Write the correction to the upper right of the original entry.

3. Give brief explanation of change

4. Initial and date the change.

3.2.2 Correcting Long Entries

To correct a long entry or information block on a form:

1. Draw a diagonal line, bottom left to upper right, through the miss entered or incorrect information.

2. Write the correction on a separate addendum page.

3. Give brief explanation of change.

4. Initial and date the changes.

5. Number the page alphanumerically

6. Place the addendum page behind the original page.

3.3 Marking Elements That Are Not Applicable

Mark each element carefully according to the instruments below, so that it will be clear that the element is unnecessary and that you have not skipped or forgotten the element.

1. Draw a diagonal line, bottom left to upper right corner, through the element that is not required.

2. Write the letters NA [Not Applicable], your initials, and the date above the line. Include comments above the line or on the form to document the reason the element is not required.

3. Where NA is indicated as an option, select this field.

The performer and reviewer must sign and date all forms, as usual, even when part or all of the form is marked “NA”.

Note: All original entries must remain legible after any corrections have been made.

3.4 Caution

The following conditions require “re-qualification”;

· When a Instrument modification has been completed, it affects the installation qualification.

· When the software or firmware has been upgraded or changed

· When this Instrument is being removed from where it was originally installed.

3.5 Re-calibration / Re-certification Requirements

The following conditions require “re-calibration / re-certification;

· For a pre-determined period of time or use.

· After any minor service has been done or replacement of parts.

· When this Instrument is being removed from where it was originally installed.

4. RESPONSIBILITIES

4.1 Validation Team

· Prepare and approve the validation protocol.

· Provide training to the personnel regarding protocol execution.

· Assure complete adherence to the protocol during the execution

· Generate amendment to the validation protocol, as required.

· Document any deviations that occur during protocol execution.

· Document Operator SOP Training.

· Provide the resources required in executing the validation protocol.

4.2 PRODUCTION MANAGER

· Review the validation protocol and the final reports

4.3 QUALITY CONTROL/ASSURANCE MANAGER

· Approve the validation protocol and the final reports

5.0 Objectives:

To verify and establish that the Autoclave is working as per recommendations of the manufacturer.

6.0 Scope:

This validation protocol is applicable to the Autoclave intended to be used for steam sterilization in LARGE VOLUME PARENTRALS SECTION.

The protocol will be implemented under the following conditions

§ The validation of sterilization process using saturated steam as the steriliant

§ Prior to the production of a new sterilizer.

§ A change In the load design or weight that would result in a load that is more difficult to sterilize.

7.0 Equipment Identification

Qualification of utilities and equipment generally includes the following activities:

• Selecting utilities and equipment construction materials, operating principles, and performance characteristics based on whether they are appropriate for their specific uses.

• Verifying that utility systems and equipment are built and installed in compliance with the design specifications (e.g., built as designed with proper materials, capacity, and

functions, and properly connected and calibrated).

• Verifying that utility systems and equipment operate in accordance with the process requirements in all anticipated operating ranges.

Equipment Name

Autoclave

Time controller

¨

2

Pressure controller

¨

2

Temperature controller

¨

3

Pressure gauge

¨

4

Safety Valve

¨

5

Thermometer

¨

Completed By:__________________ Date:_____________

Reviewed By:___________________ Date:_____________

8.0 EQUIPMENT DESCRIPTION

The Autoclave intended to be used for steam sterilizations process. It has following specifications:-

S. No.

Parameter

Range

Readability

Check

01

Timer

0—60 min

1 min

¨

02

Pressure

0—60 Lb/inch²

2.0 Lb/inch²

¨

03

Temperature

0 –150°C

0.5°C

¨

8.1 LOAD IDENTIFICATION

Nature of load

1000ml bottles

Quantity of load

2000 Bottles

8.2 STERILIZATATION CYCLE PARAMETERS

Sterilization set point

106°C

Temperature range

106°C +0.5°C

Expose time

45 minutes

8.3 Equipment Used for PROCESS VALIDATION

Equipment

Calibration

Certificate No.

Issue Date

YES

NO

Recording potentiometer

¨

¨

___________

________

Thermocouples & lead wires

¨

¨

___________

________

Biological indicator i.e.

B. stereothermophyllus

¨

¨

___________

________

Completed By:__________________ Date:_____________

Reviewed By:___________________ Date:_____________

9.0 strerilizatation procedure:

§ Place six thermocouples in the load at the slow to heat points as determined

Previously by(Heat Distribution and Heat Penetration studies)

§ Place thermocouples exterior and near to (Penetration TC)and expose to chamber steam distribution TC)

§ Place BIs (Biological Indicators) at each of the slow to heat penetration location.

§ Load autoclave extend TC out of autoclave and attach to potentiometer

§ Position one TC by controller record sensor

§ Close autoclave door

§ Perform, function check of TC .replace if defective.

§ Replace autoclave sensor chart with a new one

§ Check to make sure that cycle parameters are set

§ Set potentiometer for a 3.0 Hours scan cycle.

§ Initiate sterilization cycle and potentiometer cycle at same time

§ Allow cycle to continue until it is completed. Collect all potentiometers, controls and computer control record and place with protocol.

§ Have computer graph results and calculate Fo value. After load has cooled, remove BIs and have tested

§ Incubate BIs in incubator at 55Cº for 48 hrs

10.0 ACCEPTANCE CRITERIA

1- BDS Strip

All four colors segment of the processed indicator are black. If all other critical process parameters such as temperature, pressure and sterilization are in accordance with cycle reference.

2- Bio-Indicator i.e. B. stereothermophyllus

No growth should be observed after incubation for 48 Hours.

10.1 Results

Temperature : 106°C

Pressure : 10 Lb/inch²

Sterilization Time : 30 minutes

1- Evaluation of the BDS strip.

S.#.

Position of Indicator strip

Stick BDS-test indicator strip on

Acceptance Criteria

Results

All four color segment of indicators strip are black

Yes

No

1

¨

¨

2

¨

¨

2- Evaluation of the Bio-indicator i.e. B. stereothermophyllus

S.#.

Position of

B. stereothermophyllus

Acceptance Criteria

Observation

No growth is observed after incubation for 48 Hours

Yes

No

1

Front/top

left

Fornt/bttm

center

Middle

/centleft

¨

¨

2

Middle/

bttmleft

Rare/top

center

Rare/bttm

left

¨

¨

3

Front/top

center

Front/bottm

center

Middle/cent

left

¨

¨

4

Middle/bttm

right

Rare/top

bottom

Rare/bottm

center

¨

¨

5

Front/top

right

Front/

bottmleft

Middle/

center

¨

¨

6

Middle/

Bttm/Cent

Rare/top

right

Rare/bttm

center

¨

¨

All acceptance criteria have been met. Verified By / Date

Yes ____________No _____________ _____________

If No or N/A, explain in Comments.

Comments:_____________________________________________________________

Completed By:__________________ Date:_____________

Reviewed By:________________ Date:_____________

11.0. Incidents/Deviations

To document any discrepancy or variations noted during the execution of the Process Validation Protocol. Any action to be taken to resolve an outstanding issue is to be identified within the incident report.

INCIDENT #

DESCRIPTION OF INCIDENT

RECORDED BY

DATE

COMMENTS:

____________________________________________________________

____________________________________________________________

12.0 FINAL COMMENTS ABOUT PROCESS VALIDATION

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

13.0 SIGNATURE IDENTIFICATION SHEET

This sheet is a record of each individual who signs or initials any page included in this protocol or in the attached document. Each person shall be identified by typed or printed name.

Name Signature and Initials Company

__________________ _________________________ _____________________

__________________ _________________________ _____________________

__________________ _________________________ _____________________

__________________ _________________________ _____________________

__________________ _________________________ _____________________

__________________ ________________________ _____________________

__________________ ________________________ _____________________

__________________ ________________________ _____________________

__________________ _________________________ _____________________

FINAL APPROVAL OF QUALIFICATION

This document certifies that the process of Autoclavation has been validated as specified and complies with Standard Operating Procedures, and satisfies the requirements for cGMPs.

Name & Designation

Signature

Date

Prepared By

Tahir Ibrahim

Quality Assurance Executive

checked and Reviewed By

Abdul Hafeez

Production manager

Approved By

Tajjamal A Qurashi

Manager Quality Control

PROTOCOL TRAINING

Training Session Date : ____________________

Instructor : ____________________

Protocol Reference : ____________________

Name

Title

Signature

Date

PROCESS VALIDATION PROTOCOL -Pharmaceutical Template PDF PPT XLS

In conclusion, there is far to think about about your Computer System Validation system last to a strong inspection. Make every effort to have a system stock list put in place, the appropriate SOPs in place, and additionally to check the critical techniques and their documentation just before a powerful FDA inspection. Again, simply because the FDA can be inspecting the institution for other factors, doesn’t discount the potential the couple need to audit your pc System Validation School. As mentioned, so many of our businesses respective company procedures are carried out by way of electronic systems in this young age of technologies. Therefore, it could be useful to evaluate the Computer Validation Program whether you foresee a strong inspection or otherwise not. Having a powerful efficient Computer System Validation System put in place will help ensure the stability of the electronic documents, allocate resources better and subsequently can yield long run cost discounts to the company.

more information

DOCUMENTATION

Documentation at each stage of the process validation lifecycle is essential for effective communication in complex, lengthy, and multidisciplinary projects. Documentation is important

so that knowledge gained about a product and process is accessible and comprehensible to others involved in each stage of the lifecycle. Information transparency and accessibility are

fundamental tenets of the scientific method. They are also essential to enabling organizational units responsible and accountable for the process to make informed, science-based decisions that

ultimately support the release of a product to commerce.

The degree and type of documentation required by CGMP vary during the validation lifecycle. Documentation requirements are greatest during Stage 2, process qualification, and Stage 3,

continued process verification. Studies during these stages must conform to CGMPs and must be approved by the quality unit in accordance with the regulations .

Viral and impurity clearance studies, even when performed at small scale, also require quality

unit oversight.

CGMP documents for commercial manufacturing (i.e., the initial commercial master batch production and control record and supporting procedures) are key outputs of Stage 1,

process design. We recommend that firms diagram the process flow for the full-scale process.

Process flow diagrams should describe each unit operation, its placement in the overall process, monitoring and control points, and the component, as well as other processing material inputs

(e.g., processing aids) and expected outputs (i.e., in-process materials and finished product). It is also useful to generate and preserve process flow diagrams of the various scales as the process

design progresses to facilitate comparison and decision making about their comparability.

In conclusion, there is far to think about about your Computer System Validation system last to a strong inspection just before a powerful FDA inspection. Again, simply because the FDA can be inspecting the institution for other factors, doesn’t discount the potential the couple need to audit your pc System Validation School. As mentioned, so many of our businesses respective company procedures are carried out by way of electronic systems in this young age of technologies. Therefore, it could be useful to evaluate the Computer Validation Program whether you foresee a strong inspection or otherwise not.

GLOSSARY OF TERMS

2.1 List of Abbreviation

CGMP Current Good Manufacturing Practices

FDA Food and Drug Administration

GAMP Good Automated Manufacturing Practice

GMP Good Manufacturing Practice

IQ Installation Qualification

OQ Operation Qualification

2.2 Definitions

Acceptance Criteria Agreed standards or ranges, which must be achieved.

Critical component A component within a system where the operation, contact, data, control, alarm, or failure may have a direct impact on the quality of the product.

Critical Instrument Any instrument that directly affects product safety, purity, or efficacy.

Direct Impact System An engineering system that may have a direct impact on product quality.

Factor Acceptance Test Documenting the performance characteristics of equipment prior to shipment to site.

Impact Assessment The process of evaluating the impact of the operating, controlling alarming and failure conditions of a system on the quality of a product.

Indirect Impact System An engineering system considered not having a direct impact on product quality.

Installation Qualification Documenting the process equipment and ancillary system are constructed and installed according to pre-determined specifications and functional requirements.

No Impact System This is a system that will not have any impact, either directly or indirectly, on product quality. These systems are designed and commissioned following Good engineering Practice only.

Non-critical Component A component within a system where the operation, contact, alarm or failure may have an indirect impact or no impact on the quality of product.

Operating Limits The minimum and /or maximum values that will ensure that product and safety requirements are met.

Operational Qualification Establishing confidence that process equipment and ancillary systems are capable of consistently operating within established limits and tolerances.

Performance Qualification The documented verification that al aspects of a facility, utility or equipment that can affect product quality perform as intended meeting pre-determined acceptance criteria.

Performance Testing The process by which the performance of interdependent system is demonstrated as within the required tolerances, the output of interdependent system is demonstrated as delivering the required duty or capacity, the interdependent functions of system are interdependent to be as specified and appropriate.

Piping and Instrumentation

Diagrams Primary source of design information for utility systems and process equipment. They are used to depict the process flow, equipment configuration, process parameters, instrumentation, and materials of construction. They also are used to perform overall material and energy balances and pressure balances.

Capability of a process: Ability of a process to produce a product that will fulfill the requirements of that product. The concept of process capability can also be defined in statistical terms. (ISO 9000:2005)

Commercial manufacturing process: The manufacturing process resulting in commercial product (i.e., drug that is marketed, distributed, and sold or intended to be sold). For the purposes of this guidance, the term commercial manufacturing process does not include clinical trial or treatment IND material.

Concurrent release: Releasing for distribution a lot of finished product, manufactured following a qualification protocol, that meets the lot release criteria established in the protocol, but before the entire study protocol has been executed.

Continued process verification: Assuring that during routine production the process remains in a state of control. Performance indicators: Measurable values used to quantify quality objectives to reflect the performance of an organization, process or system, also known as performance metrics in some regions. (ICH Q10)

Process design: Defining the commercial manufacturing process based on knowledge gained through development and scale-up activities.

Process qualification: Confirming that the manufacturing process as designed is capable of reproducible commercial manufacturing.

Process validation: The collection and evaluation of data, from the process design stage through commercial production, which establishes scientific evidence that a process is capable of consistently delivering quality products.

Quality: The degree to which a set of inherent properties of a product, system, or process fulfils requirements. (ICH Q9)

State of control: A condition in which the set of controls consistently provides assurance of continued process performance and product quality. (ICH Q10)