Pharmaceutical Water System- SAMPLING CONSIDERATIONS

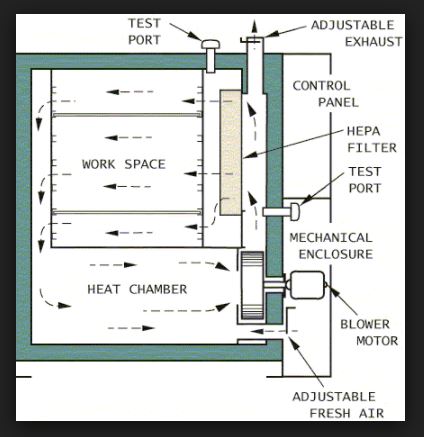

Water systems should be monitored at a frequency that is sufficient to ensure that the system is in control and continues to produce water of acceptable quality. Samples should be taken from representative locations within the processing and distribution system. Established sampling frequencies should be based on system validation data and should cover critical areas including unit operation sites. The sampling plan should take into consideration the desired attributes of the water being sampled. For example, systems for Water for Injection because of their more critical microbiological requirements, may require a more rigorous sampling frequency.

Analyses of water samples often serve two purposes: in-process control assessments and final quality control assessments. In-process control analyses are usually focused on the attributes of the water within the system. Quality control is primarily concerned with the attributes of the water delivered by the system to its various uses. The latter usually employs some sort of transfer device, often a flexible hose, to bridge the gap between the distribution system use-point valve and the actual location of water use. The issue of sample collection location and sampling procedure is often hotly debated because of the typically mixed use of the data generated from the samples, for both in-process control and quality control. In these single sample and mixed data use situations, the worst-case scenario should be utilized. In other words, samples should be collected from use points using the same delivery devices, such as hoses, and procedures, such as preliminary hose or outlet flushing, as are employed by production from those use points. Where use points per se cannot be sampled, such as hard-piped connections to equipment, special sampling ports may be used. In all cases, the sample must represent as closely as possible the quality of the water used in production. If a point of use filter is employed, sampling of the water prior to and after the filter is needed because the filter will mask the microbial control achieved by the normal operating procedures of the system.

Samples containing chemical sanitizing agents require neutralization prior to microbiological analysis. Samples for microbiological analysis should be tested immediately, or suitably refrigerated to preserve the original microbial attributes until analysis can begin. Samples of flowing water are only indicative of the concentration of planktonic (free floating) microorganisms present in the system. Biofilm microorganisms (those attached to water system surfaces) are usually present in greater numbers and are the source of the planktonic population recovered from grab samples. Microorganisms in biofilms represent a continuous source of contamination and are difficult to directly sample and quantify. Consequently, the planktonic population is usually used as an indicator of system contamination levels and is the basis for system Alert and Action Levels. The consistent appearance of elevated planktonic levels is usually an indication of advanced biofilm development in need of remedial control. System control and sanitization are key in controlling biofilm formation and the consequent planktonic population.

Sampling for chemical analyses is also done for in-process control and for quality control purposes. However, unlike microbial analyses, chemical analyses can be and often are performed using on-line instrumentation. Such on-line testing has unequivocal in-process control purposes because it is not performed on the water delivered from the system. However, unlike microbial attributes, chemical attributes are usually not significantly degraded by hoses. Therefore, through verification testing, it may be possible to show that the chemical attributes detected by the on-line instrumentation (in-process testing) are equivalent to those detected at the ends of the use point hoses (quality control testing). This again creates a single sample and mixed data use scenario. It is far better to operate the instrumentation in a continuous mode, generating large volumes of in-process data, but only using a defined small sampling of that data for QC purposes. Examples of acceptable approaches include using highest values for a given period, highest time-weighted average for a given period (from fixed or rolling sub-periods), or values at a fixed daily time. Each approach has advantages and disadvantages relative to calculation complexity and reflection of continuous quality, so the user must decide which approach is most suitable or justifiable.

Pharmaceutical Water System-CHEMICAL CONSIDERATIONS

The chemical attributes of Purified Water and Water for Injection were specified by a series of chemistry tests for various specific and nonspecific attributes with the intent of detecting chemical species indicative of incomplete or inadequate purification. While these methods could have been considered barely adequate to control the quality of these waters, they nevertheless stood the test of time. This was partly because the operation of water systems was, and still is, based on on-line conductivity measurements and specifications generally thought to preclude the failure of these archaic chemistry attribute tests.

USP moved away from these chemical attribute tests to contemporary analytical technologies for the bulk waters Purified Water and Water for Injection. The intent was to upgrade the analytical technologies without tightening the quality requirements. The two contemporary analytical technologies employed were TOC and conductivity. The TOC test replaced the test for Oxidizable substances that primarily targeted organic contaminants. A multistaged Conductivity test which detects ionic (mostly inorganic) contaminants replaced, with the exception of the test for Heavy metals, all of the inorganic chemical tests (i.e., Ammonia, Calcium, Carbon dioxide, Chloride, Sulfate).

Pharmaceutical Water Systems: Pharmaceutical Water Storage & Distribution Systems

Replacing the heavy metals attribute was considered unnecessary because (a) the source water specifications (found in the NPDWR) for individual Heavy metals were tighter than the approximate limit of detection of the Heavy metals test for USP XXII Water for Injection and Purified Water (approximately 0.1 ppm), (b) contemporary water system construction materials do not leach heavy metal contaminants, and (c) test results for this attribute have uniformly been negative—there has not been a confirmed occurrence of a singular test failure (failure of only the Heavy metals test with all other attributes passing) since the current heavy metal drinking water standards have been in place. Nevertheless, since the presence of heavy metals in Purified Water or Water for Injection could have dire consequences, its absence should at least be documented during new water system commissioning and validation or through prior test results records.

Total solids and pH are the only tests not covered by conductivity testing. The test for Total solids was considered redundant because the nonselective tests of conductivity and TOC could detect most chemical species other than silica, which could remain undetected in its colloidal form. Colloidal silica in Purified Water and Water for Injection is easily removed by most water pretreatment steps and even if present in the water, constitutes no medical or functional hazard except under extreme and rare situations. In such extreme situations, other attribute extremes are also likely to be detected. It is, however, the user’s responsibility to ensure fitness for use. If silica is a significant component in the source water, and the purification unit operations could be operated or fail and selectively allow silica to be released into the finished water (in the absence of co-contaminants detectable by conductivity), then either silica-specific or a total solids type testing should be utilized to monitor and control this rare problem.

The pH attribute was eventually recognized to be redundant to the conductivity test (which included pH as an aspect of the test and specification); therefore, pH was dropped as a separate attribute test.

The rationale used by USP to establish its conductivity specification took into consideration the conductivity contributed by the two least conductive former attributes of Chloride and Ammonia, thereby precluding their failure had those wet chemistry tests been performed. In essence, the Stage 3 conductivity specifications (see Water Conductivity 645 ) were established from the sum of the conductivities of the limit concentrations of chloride ions (from pH 5.0 to 6.2) and ammonia ions (from pH 6.3 to 7.0), plus the unavoidable contribution of other conductivity-contributing ions from water (H+ and OH–), dissolved atmospheric CO2 (as HCO3–), and an electro-balancing quantity of either Na+ of Cl–, depending on the pH-induced ionic imbalance (see Table 1). The Stage 2 conductivity specification is the lowest value on this table, 2.1 µS/cm. The Stage 1 specifications, designed primarily for on-line measurements, were derived essentially by summing the lowest values in the contributing ion columns for each of a series of tables similar to Table 1, created for each 5 increment between 0 and 100 . For example purposes, the italicized values in Table 1, the conductivity data table for 25 , were summed to yield a conservative value of 1.3 µS/cm, the Stage 1 specification for a nontemperature compensated, nonatmosphere equilibrated water sample that actual had a measured temperature of 25 to 29 . Each 5 increment table was similarly treated to yield the individual values listed in the table of Stage 1 specifications (see Water Conductivity 645 ).

As stated above, this rather radical change to utilizing a conductivity attribute as well as the inclusion of a TOC attribute allowed for on-line measurements. This was a major philosophical change and allowed major savings to be realized by industry. The TOC and conductivity tests can also be performed “off-line” in the laboratories using collected samples, though sample collection tends to introduce opportunities for adventitious contamination that can cause false high readings. The collection of on-line data is not, however, without challenges. The continuous readings tend to create voluminous amounts of data where before only a single data point was available. As stated under Sampling Considerations, continuous in-process data is excellent for understanding how a water system performs during all of its various usage and maintenance events in real time, but is too much data for QC purposes. Therefore, a justifiable fraction or averaging of the data can be used that is still representative of the overall water quality being used.

Packaged waters present a particular dilemma relative to the attributes of conductivity and TOC. The package itself is the source of chemicals (inorganics and organics) that leach over time into the water and can easily be detected. The irony of organic leaching from plastic packaging is that when the Oxidizable substances test was the only “organic contaminant” test for both bulk and packaged waters, that test’s insensitivity to those organic leachables rendered their presence in packaged water at high concentrations (many times the TOC specification for bulk water) virtually undetectable. Similarly, glass containers can also leach inorganics, such as sodium, which are easily detected by conductivity, but are undetected by the wet chemistry tests for water (other than pH or Total solids). Most of these leachables are considered harmless by current perceptions and standards at the rather significant concentrations present. Nevertheless, they effectively degrade the quality of the high-purity waters placed into these packaging system. Some packaging materials contain more leachables than others and may not be as suitable for holding water and maintaining its purity.

The attributes of conductivity and TOC tend to reveal more about the packaging leachables than they do about the water’s original purity. These “allowed” leachables could render the packaged versions of originally equivalent bulk water essentially unsuitable for many uses where the bulk waters are perfectly adequate.

[PPT PDF] Pharmaceutical Water System Design Validation -SAMPLING CONSIDERATIONS pdf [PPT PDF] Pharmaceutical Water System Design Validation -SAMPLING CONSIDERATIONS

Pharmaceutical Water System-MICROBIAL CONSIDERATIONS

The major exogenous source of microbial contamination of bulk pharmaceutical water is source or feed water. Feed water quality must, at a minimum, meet the quality attributes of Drinking Water for which the level of coliforms are regulated. A wide variety of other microorganisms, chiefly Gram-negative bacteria, may be present in the incoming water. These microorganisms may compromise subsequent purification steps. Examples of other potential exogenous sources of microbial contamination include unprotected vents, faulty air filters, ruptured rupture disks, backflow from contaminated outlets, unsanitized distribution system “openings” including routine component replacements, inspections, repairs, and expansions, inadequate drain and air-breaks, and replacement activated carbon, deionizer resins, and regenerant chemicals. In these situations, the exogenous contaminants may not be normal aquatic bacteria but rather microorganisms of soil or even human origin. The detection of nonaquatic microorganisms may be an indication of a system component failure, which should trigger investigations that will remediate their source. Sufficient care should be given to system design and maintenance in order to minimize microbial contamination from these exogenous sources.

Unit operations can be a major source of endogenous microbial contamination. Microorganisms present in feed water may adsorb to carbon bed, deionizer resins, filter membranes, and other unit operation surfaces and initiate the formation of a biofilm. In a high-purity water system, biofilm is an adaptive response by certain microorganisms to survive in this low nutrient environment. Downstream colonization can occur when microorganisms are shed from existing biofilm-colonized surfaces and carried to other areas of the water system. Microorganisms may also attach to suspended particles such as carbon bed fines or fractured resin particles. When the microorganisms become planktonic, they serve as a source of contamination to subsequent purification equipment (compromising its functionality) and to distribution systems.

Another source of endogenous microbial contamination is the distribution system itself. Microorganisms can colonize pipe surfaces, rough welds, badly aligned flanges, valves, and unidentified dead legs, where they proliferate, forming a biofilm. The smoothness and composition of the surface may affect the rate of initial microbial adsorption, but once adsorbed, biofilm development, unless otherwise inhibited by sanitizing conditions, will occur regardless of the surface. Once formed, the biofilm becomes a continuous source of microbial contamination.

![[PPT PDF] Pharmaceutical Water System Design Validation -SAMPLING CONSIDERATIONS](https://pharmawiki.in/wp-content/uploads/2017/11/PPT-PDF-Pharmaceutical-Water-System-Design-Validation-SAMPLING-CONSIDERATIONS.jpg)

ENDOTOXIN CONSIDERATIONS

Endotoxins are lipopolysaccharides found in and shed from the cell envelope that is external to the cell wall of Gram-negative bacteria. Gram-negative bacteria that form biofilms can become a source of endotoxins in pharmaceutical waters. Endotoxins may occur as clusters of lipopolysaccharide molecules associated with living microorganisms, fragments of dead microorganisms or the polysaccharide slime surrounding biofilm bacteria, or as free molecules. The free form of endotoxins may be released from cell surfaces of the bacteria that colonize the water system, or from the feed water that may enter the water system. Because of the multiplicity of endotoxin sources in a water system, endotoxin quantitation in a water system is not a good indicator of the level of biofilm abundance within a water system.

Pharmaceutical Water System Design Validation – Microbial Testing of Water

Endotoxin levels may be minimized by controlling the introduction of free endotoxins and microorganisms in the feed water and minimizing microbial proliferation in the system. This may be accomplished through the normal exclusion or removal action afforded by various unit operations within the treatment system as well as through system sanitization. Other control methods include the use of ultrafilters or charge-modified filters, either in-line or at the point of use. The presence of endotoxins may be monitored as described in the general test chapter Bacterial Endotoxins Test 85 .

MICROBIAL ENUMERATION CONSIDERATIONS

The objective of a water system microbiological monitoring program is to provide sufficient information to control and assess the microbiological quality of the water produced. Product quality requirements should dictate water quality specifications. An appropriate level of control may be maintained by using data trending techniques and, if necessary, limiting specific contraindicated microorganisms. Consequently, it may not be necessary to detect all of the microorganisms species present in a given sample. The monitoring program and methodology should indicate adverse trends and detect microorganisms that are potentially harmful to the finished product, process, or consumer. Final selection of method variables should be based on the individual requirements of the system being monitored.

It should be recognized that there is no single method that is capable of detecting all of the potential microbial contaminants of a water system. The methods used for microbial monitoring should be capable of isolating the numbers and types of organisms that have been deemed significant relative to in-process system control and product impact for each individual system. Several criteria should be considered when selecting a method to monitor the microbial content of a pharmaceutical water system. These include method sensitivity, range of organisms types or species recovered, sample processing throughput, incubation period, cost, and methodological complexity. An alternative consideration to the use of the classical “culture” approaches is a sophisticated instrumental or rapid test method that may yield more timely results. However, care must be exercised in selecting such an alternative approach to ensure that it has both sensitivity and correlation to classical culture approaches, which are generally considered the accepted standards for microbial enumeration.

Pharmaceutical Water System Design Operation & Validation

Consideration should also be given to the timeliness of microbial enumeration testing after sample collection. The number of detectable planktonic bacteria in a sample collected in a scrupulously clean sample container will usually drop as time passes. The planktonic bacteria within the sample will tend to either die or to irretrievably adsorb to the container walls reducing the number of viable planktonic bacteria that can be withdrawn from the sample for testing. The opposite effect can also occur if the sample container is not scrupulously clean and contains a low concentration of some microbial nutrient that could promote microbial growth within the sample container. Because the number of recoverable bacteria in a sample can change positively or negatively over time after sample collection, it is best to test the samples as soon as possible after being collected. If it is not possible to test the sample within about 2 hours of collection, the sample should be held at refrigerated temperatures (2 to 8 ) for a maximum of about 12 hours to maintain the microbial attributes until analysis. In situations where even this is not possible (such as when using off-site contract laboratories), testing of these refrigerated samples should be performed within 48 hours after sample collection. In the delayed testing scenario, the recovered microbial levels may not be the same as would have been recovered had the testing been performed shortly after sample collection. Therefore, studies should be performed to determine the existence and acceptability of potential microbial enumeration aberrations caused by protracted testing delays.

Source : USP

Expert Committee : (PW05) Pharmaceutical Waters 05

USP29–NF24 Page 3056

Pharmacopeial Forum : Volume No. 30(5) Page 1744

Pharmaceutical Water System Ppt,

Pharmaceutical Water Systems,

Purified Water Specification As Per Usp,

Pharmaceutical Water System Design Operation And Validation Pdf,

pharmaceutical water system design operation and validation,

pharmaceutical water system ppt – What is Pharmaceutical water,

purified water & Water for Injection SOP as per usp,

Pharmaceutical Water Systems: Storage & Distribution Systems,

pharmaceutical water system : Inspection of Pharmaceutical water systems,

pharmaceutical water Production : Water purification systems,

Pharmaceutical Water Systems: Types: Water quality specifications,

Pharmaceutical Water System: principles for pharmaceutical water systems

![[PPT PDF] Pharmaceutical Water System Validation - IDENTIFICATION OF MICROORGANISMS](https://pharmawiki.in/wp-content/uploads/2017/11/PPT-PDF-Pharmaceutical-Water-System-Validation-IDENTIFICATION-OF-MICROORGANISMS.jpg)

![[PPT PDF] Pharmaceutical Water System Design Validation -SAMPLING CONSIDERATIONS](https://pharmawiki.in/wp-content/uploads/2017/11/PPT-PDF-Pharmaceutical-Water-System-Design-Validation-SAMPLING-CONSIDERATIONS.jpg)